Concrete Paver

- Model

- CP6000,CP8000

Review

Description

<iframe width="560" height="315" loading="lazy" src="https://www.youtube.com/embed/xyT-JZvQrMw" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

Technology source and development

The technology of our slip-form concrete paver is from USA PRO-HOFF company. The machine travel by two tracks, with auto traveling and auto leveling control system, can finish concrete distribution, smooth, vibration, tamper, extrusion to road shape by one time, and this machine also can insert steel bars from middle and two sides of the road.

Main Technical Specification

Item | Unit |

ZM-CP6000 |

ZM-CP8000 |

Paving Width | mm | 3400-6000 | 4250-8000 |

Paving Thickness | mm | 0-350 | 0-350 |

Paving Speed | m/min |

0-10 |

0-10 |

Drive System | Full Hydraulic | Full Hydraulic | |

Running System | Track Shoe | Track Shoe | |

Engine Model | TAD620VE(Volvo) | TAD721VE(Volvo) | |

Engine Power | kw | 145 | 195 |

Engine Speed | rpm | 2300 | 2300 |

Pavement Evenness | mm/3m | 3mm/3m | 3mm/3m |

Vibration Bar | High frequency & Hydraulic drive | High frequency & Hydraulic drive | |

Overall Size | mm | 4020*7290*2770 | 4020*9290*2770 |

Machine Weight | t |

22 |

25 |

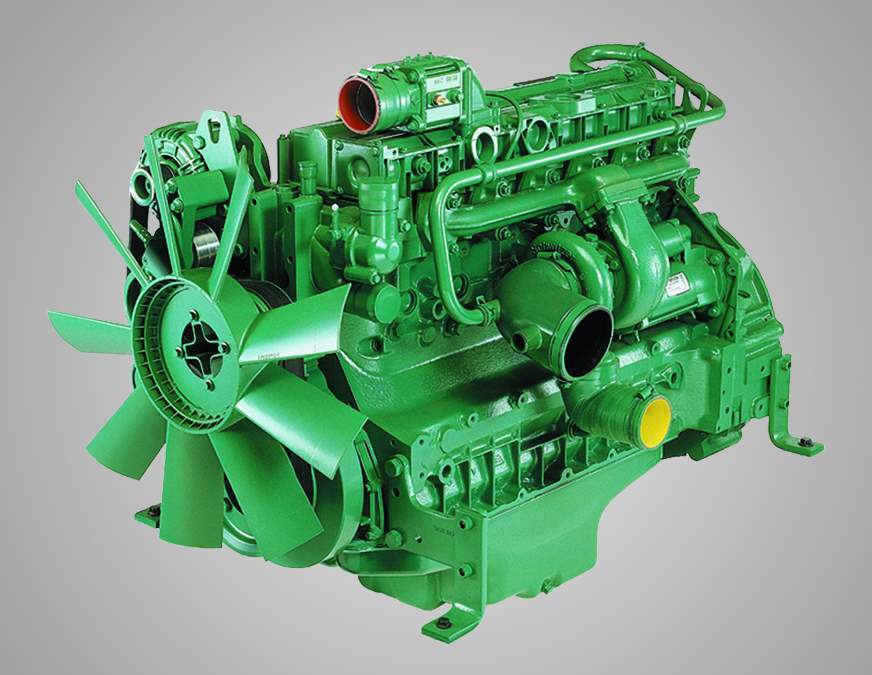

Engine

Volvo water-cooled engine, powerful, high-torque reservation, low fuel consumption, emission in conformity with Europe environment.

Vibration Device

Super-high frequency, strong vibration, high density of top-side paving.

Auto Levelling System

Auto levelling and tracing systems ensures paving surface flatness and road straightness.

Centralized Lubrication

Centralized lubrication can auto charge lubrication grease to high-temperature and motive components, lengthen wear-out period effectively, greatly improve reliability of tamper and feeding.

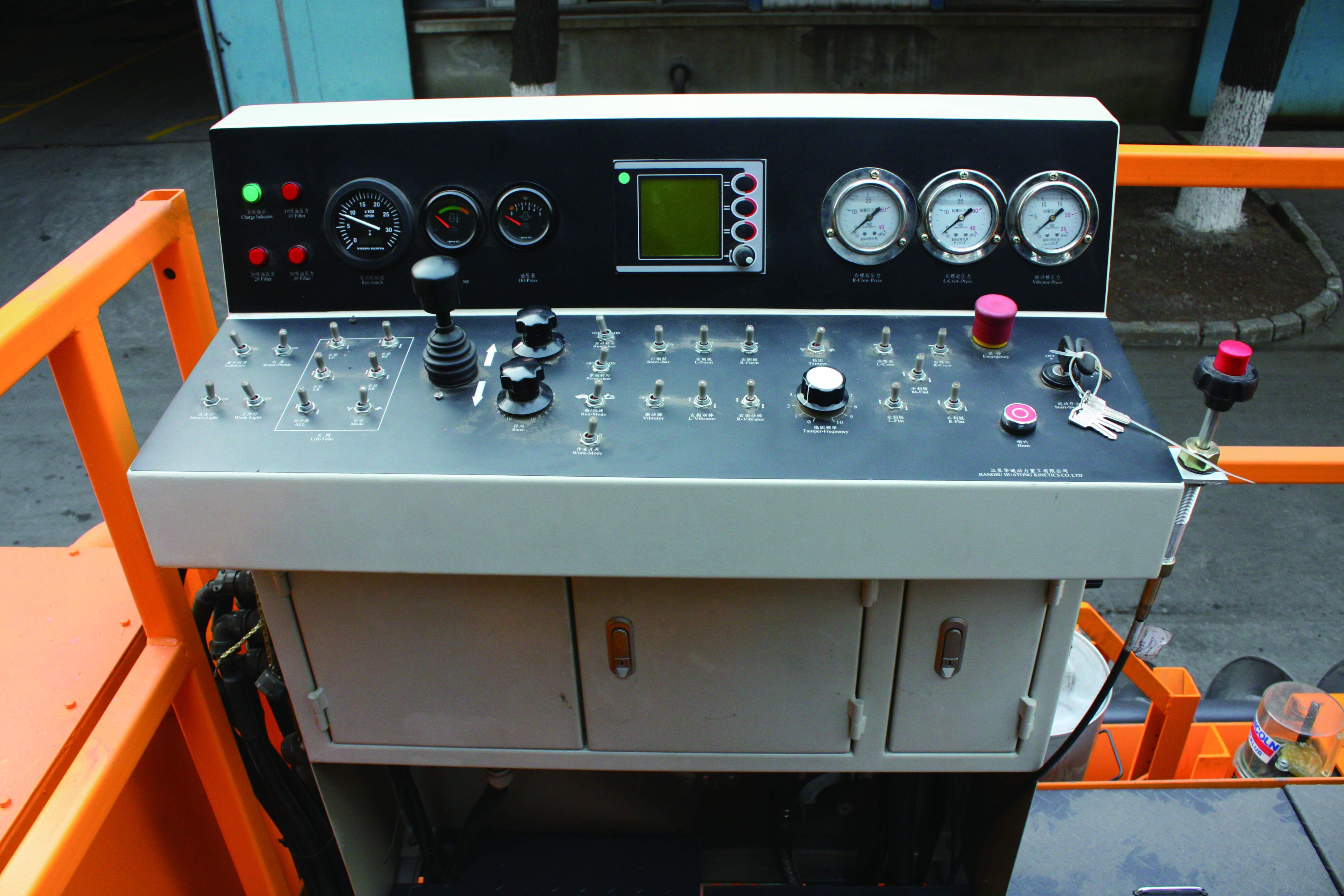

Console

User-friendly interface with display, real-time monitoring for machine status.

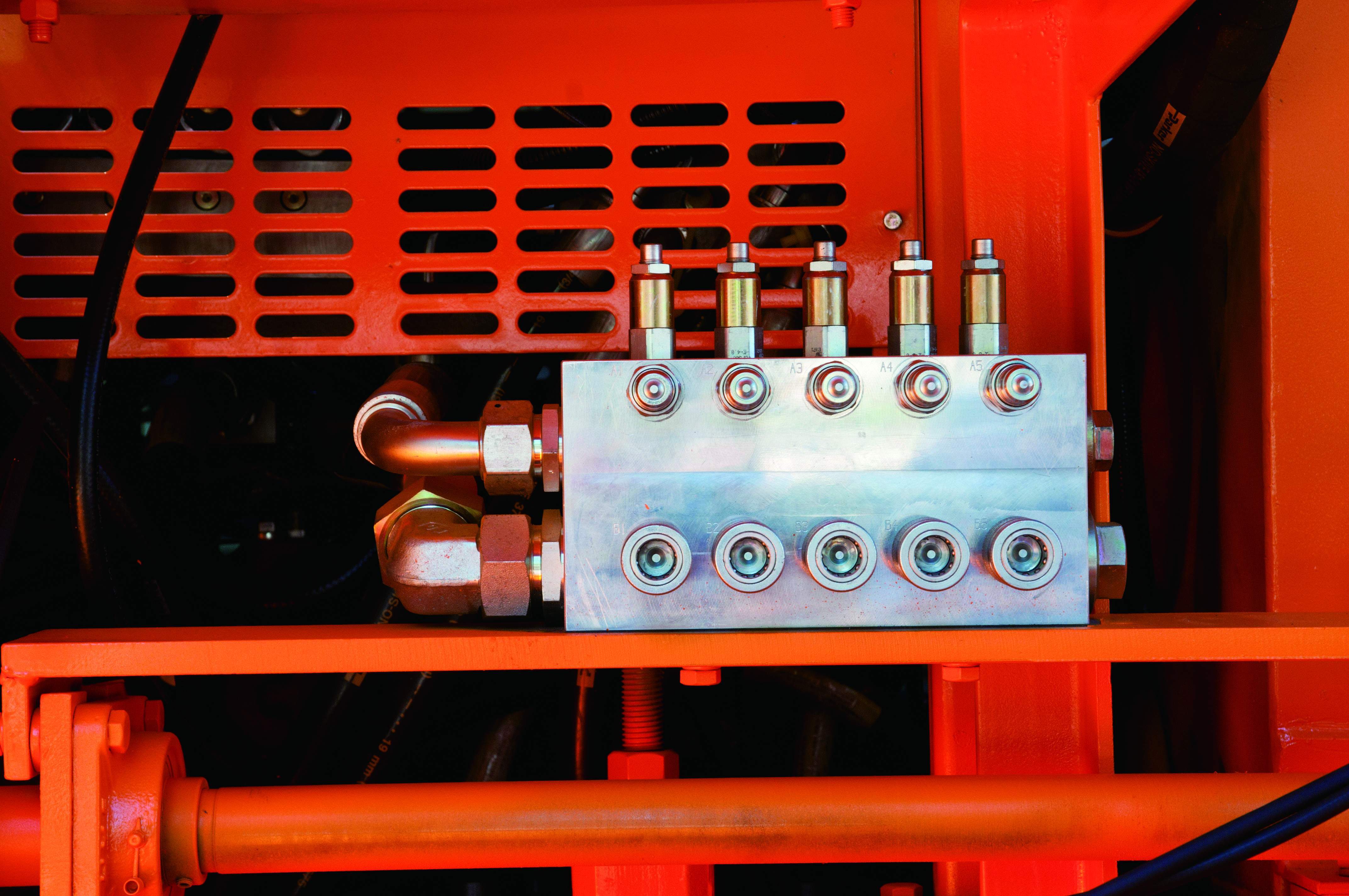

Hydraulic Transmission

Hydraulic transmission for vibration bar, stepless frequency conversion to supply optimum frequency for all kinds of concrete.

Tamper Bar

Multi-segments and multi-bars design to ensure further compacting and mud extraction.

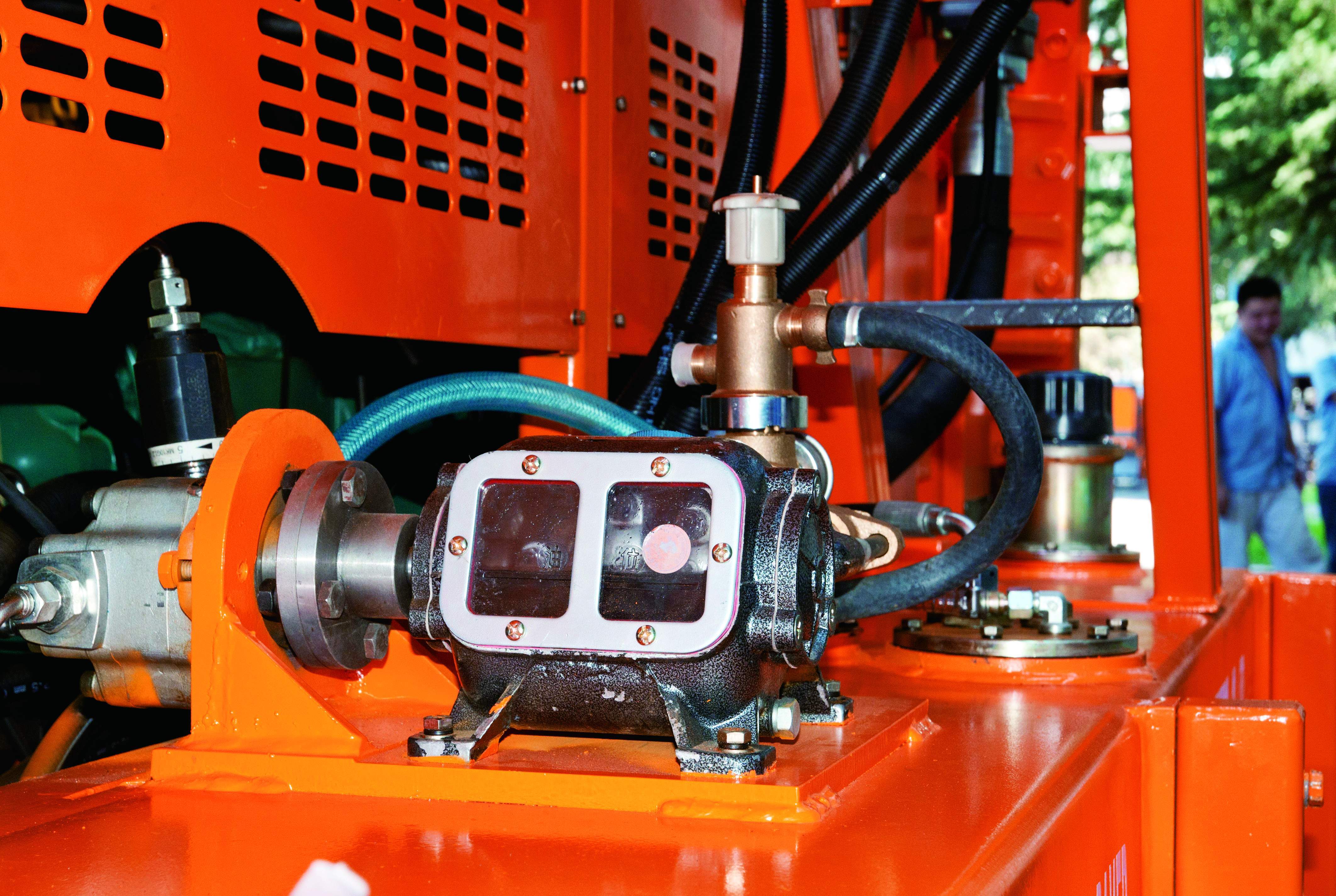

High Pressure Water Jet

To clean the machine effectively and to prevent concrete from hardening freezing on machine.

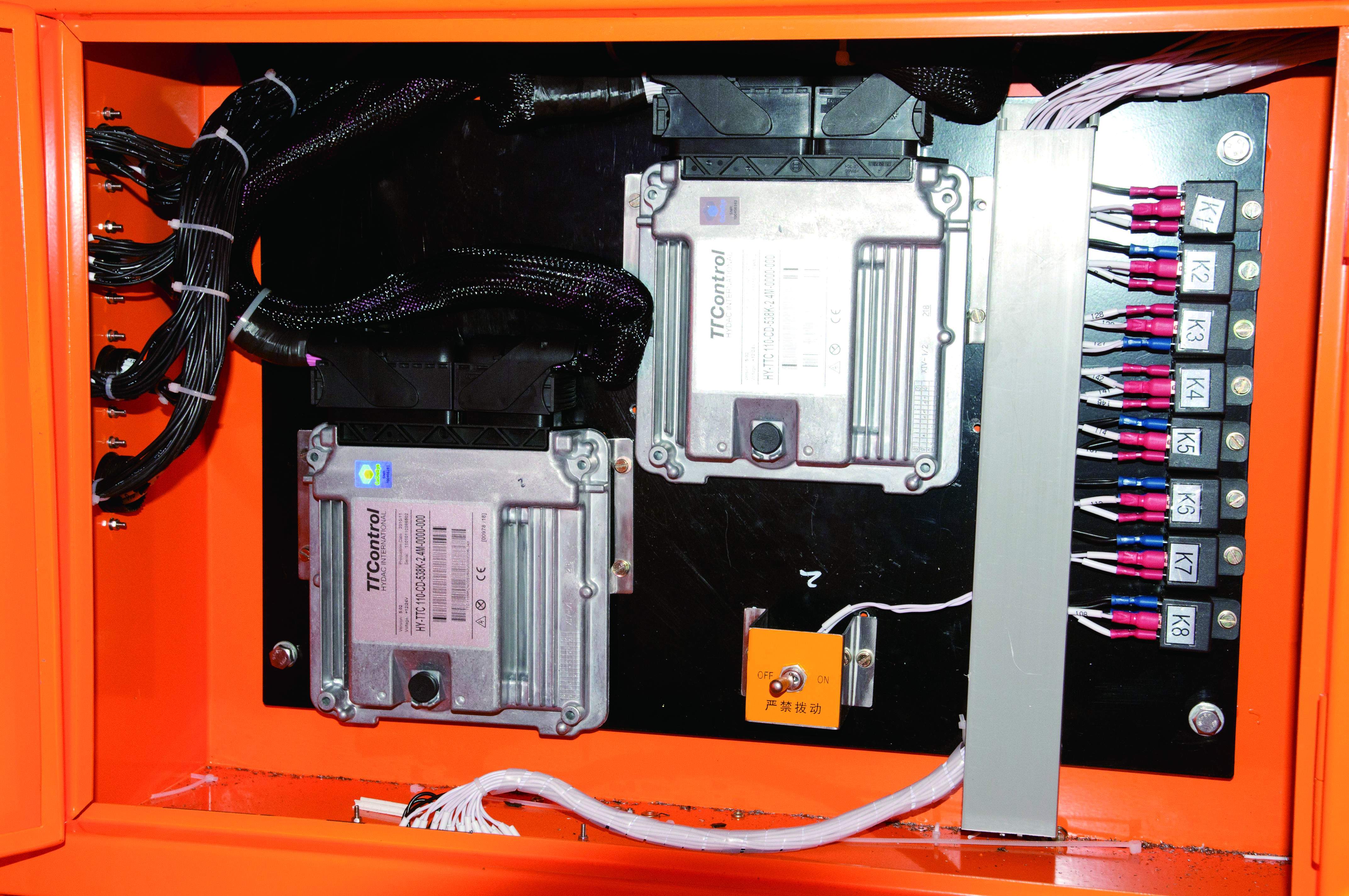

Control System

Micro-computer system with self-diagnostic capability.

Pictures on the jobsite